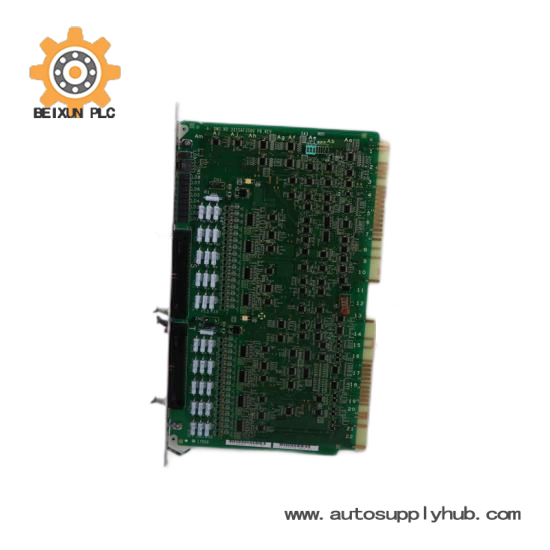

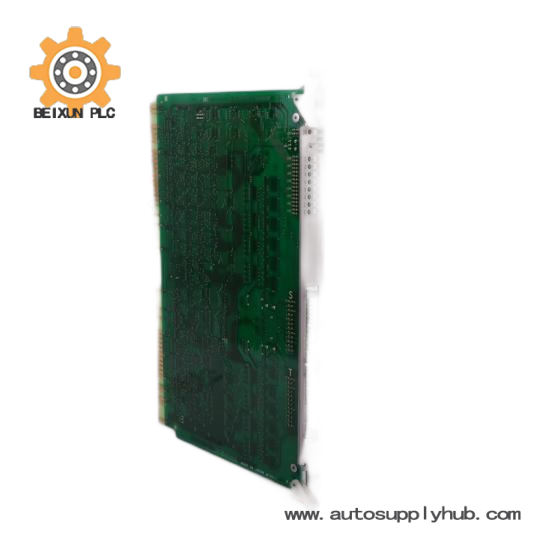

Model:BLII-D 150A

Brand:OKUMA

Application Type:Precision CNC

Max Cutting Power:150 kW

Operating Voltage:AC 380 V

Maximum RPM:24,000 RPM

Table Size:3,000 x 1,500 mm

Max Workpiece Weight:5,000 kg

Precision Accuracy:+/- 0.002 mm

Coolant Type:Water-based

Spindle Type:Variable Frequency Drive (VFD)

Control System:Okuma OSP-AI CNC

Network Connectivity:Ethernet, USB, RS-232

Software Compatibility:Windows, Linux

Maintenance Interval:Every 2,000 hours

Dimensions (WxHxD):2,500 x 1,200 x 1,000 mm

Weight:3,500 kg

Engineered for high-precision operations, the OKUMA BLII-D 150A is a game-changer in the world of advanced manufacturing. With its robust construction and state-of-the-art technology, it ensures exceptional performance in demanding applications.

Featuring a maximum cutting power of 150 kW, this CNC module can handle complex jobs with ease, ensuring that every cut meets the highest standards of precision and quality.

Equipped with a powerful Variable Frequency Drive (VFD) spindle, it offers a maximum RPM of 24,000, enabling swift and accurate machining processes. The large 3,000 x 1,500 mm worktable accommodates heavy workpieces up to 5,000 kg, making it versatile for a broad spectrum of industries.

The precision accuracy of +/- 0.002 mm is unparalleled, ensuring that every manufactured part meets the most stringent tolerances. The use of water-based coolant further enhances the safety and environmental sustainability of the operation.

With compatibility across Windows and Linux operating systems, the Okuma OSP-AI CNC control system integrates seamlessly with modern automation workflows, streamlining setup and operation. The Ethernet connectivity allows for easy data exchange and remote monitoring, optimizing productivity and maintenance schedules.

There are no reviews yet.